Component Journal

Record component installations, removals, and replacements using the Component Journal worksheet - the primary tool for documenting component operations.

Understanding Component Journal

What is Component Journal?

Component Journal = Worksheet for recording component operations before posting to ledger

How It Works:

-

Open Component Journal

-

Add journal lines (one per component operation)

-

Fill in: Asset, Item, Entry Type, Quantity, etc.

-

Post journal

-

Component Entries created

-

Complete audit trail

Similar To:

-

Item Journal (for inventory)

-

Asset Journal (for holder changes)

-

General Journal (for accounting)

Component Journal vs. Component Entries

Component Journal = Temporary worksheet (editable)

Component Entries = Permanent ledger (not editable)

| Aspect

|

Component Journal

|

Component Entries

| | --- | --- | --- | |

Type

|

Worksheet

|

Ledger

| |

Editable

|

Yes (before posting)

|

No (permanent)

| |

Purpose

|

Record operations

|

History/audit trail

| |

Created

|

Manually by users

|

Automatically on posting

| |

Deleted

|

Can delete lines

|

Cannot delete entries

|

Workflow: Component Journal → Post → Component Entries

Opening Component Journal

Search Method

Step 1: Search

-

Press Alt+Q (Tell Me)

-

Type "Component Journal"

-

Select "Asset Component Journal"

-

Page opens

From Role Center

Method: Navigate → Maintenance → Component Journal

Result: Component Journal opens

Journal Batch Management

What is a Batch?

Batch = Container for journal lines

Purpose:

-

Group related operations

-

Separate different types of work

-

Multiple users can work in different batches simultaneously

Examples:

-

MAINTENANCE (scheduled maintenance lines)

-

REPAIR (repair operation lines)

-

INSTALLATION (new component installs)

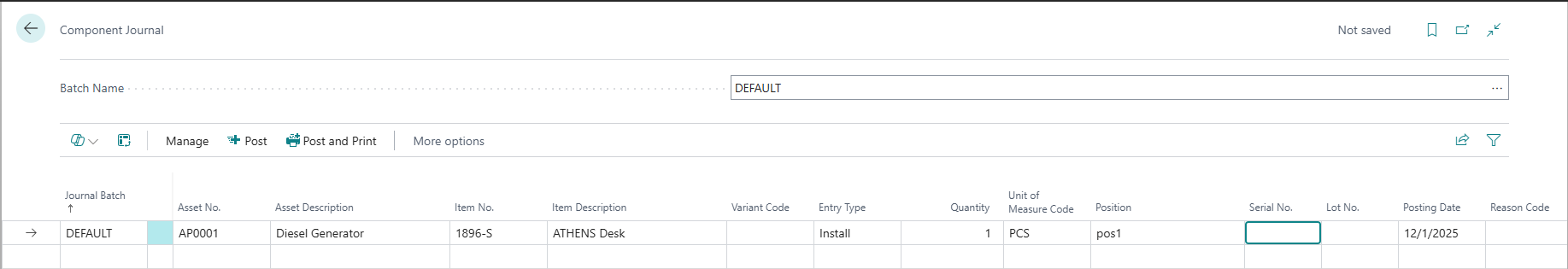

Batch Selector

Location: Top of Component Journal page

Field: "Batch Name"

Default: DEFAULT (auto-created if no batches exist)

Creating New Batch

Step 1: Open Batch Selector

-

Click Batch Name field

-

Click lookup (dropdown arrow)

-

Batch list opens

Step 2: Create New Batch

-

Click New

-

Name: Enter batch code (e.g., MAINTENANCE)

-

Description: Enter description (e.g., "Scheduled Maintenance")

-

Click OK

Step 3: Select Batch

-

New batch now available in selector

-

Switch between batches as needed

Understanding Journal Lines

Journal Line = One Component Operation

Each Line Records:

-

Which asset (Asset No.)

-

Which component (Item No.)

-

What operation (Entry Type)

-

How many (Quantity)

-

Where in asset (Position)

-

When (Posting Date)

-

Why (Reason Code)

Multiple Lines: Create multiple lines for multiple operations

Journal Line Fields

Asset No. (Required)

Type: Code[20]

Required: Yes

Links To: Asset Pro Asset table

Purpose: Which asset this component is for

Lookup: Opens Asset List

Validation:

-

Asset must exist

-

Asset must not be blocked

Auto-Fill: Asset Description

Example: VEH-001 (Fleet Truck)

Asset Description (Read-Only)

Type: Text[100]

Auto-Populated: From asset record

Editable: No

Purpose: Asset name for reference

Item No. (Required)

Type: Code[20]

Required: Yes

Links To: Business Central Item table

Purpose: Which component (part)

Lookup: Opens Item List

Validation: Item must exist in BC

Auto-Fill: Item Description, Unit of Measure Code

Example: FILTER-OIL (Engine Oil Filter)

Item Description (Read-Only)

Type: Text[100]

Auto-Populated: From item record

Editable: No

Purpose: Item name for reference

Variant Code (Optional)

Type: Code[10]

Links To: Item Variant

Optional: Yes

Purpose: Specific item variant

Example: Item "TIRE", Variant "17-INCH"

When to Use: Items with multiple variants

Entry Type (Required)

Type: Enum

Required: Yes

Options: Install, Remove, Replace, Adjustment

Purpose: What operation is being performed

Critical: Determines interpretation of operation

Default: None (must select)

[Screenshot Placeholder: Entry Type dropdown]

Quantity (Required)

Type: Decimal

Required: Yes

Precision: 0-5 decimals

Purpose: How many components

Sign Convention:

-

Install: Positive (e.g., 4 for 4 tires)

-

Remove: Negative (e.g., -1 for 1 drive) OR positive with Remove type

-

Replace: Positive (new component qty)

-

Adjustment: Positive or negative (correction)

Example: 5 (five quarts of oil)

Unit of Measure Code (Optional)

Type: Code[10]

Links To: Item Unit of Measure

Auto-Filled: From Item's Base Unit of Measure

Purpose: Unit for quantity

Examples: PCS (pieces), QT (quarts), GAL (gallons), EA (each)

Can Override: Yes, if item has multiple UOMs

Position (Optional, Recommended)

Type: Text[50]

Optional: Yes (but highly recommended)

Purpose: Physical location within asset

Examples:

-

"Front Left Wheel"

-

"Disk Bay 3"

-

"Engine Compartment"

-

"Slot A1"

-

"Cartridge Tray 2"

Benefit: Precise component tracking, faster maintenance

Best Practice: Always fill when position matters

Serial No. (Optional)

Type: Code[50]

Optional: Yes

Purpose: Serial number for serialized components

Examples:

-

Hard drive: HDD-SN-8472947

-

Memory module: MEM-12345678

-

Battery: BAT-SN-2024-001

When to Use:

-

Serialized parts

-

Warranty tracking

-

Expensive components

-

RMA requirements

Lot No. (Optional)

Type: Code[50]

Optional: Yes

Purpose: Lot/batch number

Examples:

-

Filter lot: LOT-2024-Q1-001

-

Oil batch: BATCH-5W30-2024

When to Use:

-

Lot-tracked items

-

Quality control

-

Recall management

Posting Date (Required)

Type: Date

Required: Yes

Default: Today's date (WorkDate)

Purpose: When component operation occurred

Can Change: Yes (for backdating)

Example: 2024-03-15

Reason Code (Optional, Recommended)

Type: Code[10]

Optional: Yes

Links To: BC Reason Code

Purpose: Why component operation happened

Common Codes:

-

MAINTENANCE - Scheduled maintenance

-

REPAIR - Repair/replacement

-

FAILURE - Component failure

-

UPGRADE - Component upgrade

-

RECALL - Manufacturer recall

-

AUDIT - Inventory audit adjustment

Benefit: Reporting by reason, clear audit trail

Document No. (Optional)

Type: Code[20]

Optional: Yes

Purpose: Internal document reference

Examples:

-

COMP-JNL-2024-001

-

WO-12345 (work order)

-

MAINT-Q1-001

Usage: Group related operations, link to work orders

External Document No. (Optional)

Type: Code[35]

Optional: Yes

Purpose: External reference

Examples:

-

Work Order: WO-2024-12345

-

Service Ticket: TICKET-8472

-

Purchase Order: PO-VEN-001

-

RMA: RMA-VENDOR-789

Benefit: Complete traceability to external systems

Creating Journal Lines

Adding First Line

Step 1: Position Cursor

-

Component Journal open

-

Cursor in first empty line

Step 2: Fill Required Fields

-

Asset No.: Select asset (lookup or type)

-

Item No.: Select component (lookup or type)

-

Entry Type: Select (Install/Remove/Replace/Adjustment)

-

Quantity: Enter quantity

-

Posting Date: Verify/change date

Step 3: Fill Optional Fields

-

Position: Enter location (recommended)

-

Serial No.: Enter if serialized

-

Reason Code: Select reason (recommended)

-

External Document No.: Enter reference

Step 4: Move to Next Line

-

Press Enter or Down arrow

-

New line ready

Adding Multiple Lines

Method 1: Sequential Entry

-

Fill line 1

-

Press Enter

-

Fill line 2

-

Repeat

Method 2: Copy Similar Lines

-

Fill first line completely

-

Copy relevant fields to next line

-

Change only what's different

Example: 4 tires installation

-

Line 1: Asset VEH-001, Item TIRE, Position "Front Left", Qty 1

-

Line 2: Asset VEH-001, Item TIRE, Position "Front Right", Qty 1

-

Line 3: Asset VEH-001, Item TIRE, Position "Rear Left", Qty 1

-

Line 4: Asset VEH-001, Item TIRE, Position "Rear Right", Qty 1

Entry Type Examples

Install Entry

Purpose: Adding component to asset

Quantity: Positive

Example 1: Install Hard Drive

-

Asset No.: SRV-001

-

Item No.: HDD-2TB

-

Entry Type: Install

-

Quantity: 1

-

Position: "Bay 3"

-

Serial No.: HDD-12345

-

Reason Code: UPGRADE

Result: Hard drive installation documented

Remove Entry

Purpose: Taking component out of asset

Quantity: Negative (or positive with Remove type)

Example 2: Remove Defective Memory

-

Asset No.: SRV-001

-

Item No.: MEM-8GB

-

Entry Type: Remove

-

Quantity: 1

-

Position: "Slot A2"

-

Serial No.: MEM-DEFECT-001

-

Reason Code: FAILURE

-

External Document No.: RMA-2024-001

Result: Removal documented for RMA

Replace Entry

Purpose: Replacing component (old out, new in)

Quantity: Positive (new component qty)

Example 3: Replace Oil Filter

-

Asset No.: VEH-001

-

Item No.: FILTER-OIL

-

Entry Type: Replace

-

Quantity: 1

-

Reason Code: MAINTENANCE

-

External Document No.: WO-2024-045

Result: Filter replacement documented

Note: Replace = convenience type for remove + install in one entry

Adjustment Entry

Purpose: Correct component records

Quantity: Positive or negative (correction)

Example 4: Adjust After Physical Count

-

Asset No.: PRINTER-001

-

Item No.: TONER-BLK

-

Entry Type: Adjustment

-

Quantity: 1 (found one more than recorded)

-

Reason Code: AUDIT

Result: Record corrected to match physical reality

Complete Use Cases

Use Case 1: Vehicle Oil Change

Scenario: Scheduled oil change for Fleet Truck VEH-001

Components:

-

Oil filter

-

Engine oil (5 quarts)

Journal Lines:

Line 1: Oil Filter Replacement

-

Asset No.: VEH-001

-

Item No.: FILTER-OIL

-

Entry Type: Replace

-

Quantity: 1

-

Posting Date: 2024-03-15

-

Reason Code: MAINTENANCE

-

External Document No.: WO-2024-045

Line 2: Engine Oil Installation

-

Asset No.: VEH-001

-

Item No.: OIL-5W30

-

Entry Type: Install

-

Quantity: 5

-

Unit of Measure Code: QT

-

Posting Date: 2024-03-15

-

Reason Code: MAINTENANCE

-

External Document No.: WO-2024-045

Post: Complete oil change documented

[Screenshot Placeholder: Oil change journal lines]

Use Case 2: Server Hard Drive Replacement

Scenario: Failed hard drive in server, replacing with new drive

Components:

-

Old drive (defective)

-

New drive (replacement)

Journal Lines:

Line 1: Remove Defective Drive

-

Asset No.: SRV-001

-

Item No.: HDD-2TB

-

Entry Type: Remove

-

Quantity: 1

-

Position: "Bay 3"

-

Serial No.: HDD-OLD-12345

-

Posting Date: 2024-03-20

-

Reason Code: FAILURE

-

External Document No.: TICKET-8472

Line 2: Install New Drive

-

Asset No.: SRV-001

-

Item No.: HDD-2TB

-

Entry Type: Install

-

Quantity: 1

-

Position: "Bay 3"

-

Serial No.: HDD-NEW-67890

-

Posting Date: 2024-03-20

-

Reason Code: REPAIR

-

External Document No.: TICKET-8472

Alternative: Use single Replace entry with new serial number

Post: Drive replacement completely documented with serials

Use Case 3: Printer Toner Replacement

Scenario: Replace empty toner cartridge

Journal Line:

-

Asset No.: PRINTER-LAB-001

-

Item No.: TONER-BLK

-

Entry Type: Replace

-

Quantity: 1

-

Posting Date: 2024-03-18

-

Reason Code: MAINTENANCE

Post: Consumable usage tracked

Use Case 4: HVAC Annual Maintenance

Scenario: Annual maintenance for HVAC unit - multiple components

Components:

-

2x Air filters

-

1x Belt

-

1x Lubricant

Journal Lines:

Line 1: Air Filters

-

Asset No.: HVAC-001

-

Item No.: FILTER-AIR-20X25

-

Entry Type: Replace

-

Quantity: 2

-

Posting Date: 2024-04-01

-

Reason Code: MAINTENANCE

-

External Document No.: MAINT-ANNUAL-001

Line 2: Belt

-

Asset No.: HVAC-001

-

Item No.: BELT-V-A42

-

Entry Type: Replace

-

Quantity: 1

-

Posting Date: 2024-04-01

-

Reason Code: MAINTENANCE

-

External Document No.: MAINT-ANNUAL-001

Line 3: Lubricant

-

Asset No.: HVAC-001

-

Item No.: LUBE-HVAC

-

Entry Type: Install

-

Quantity: 1

-

Unit of Measure Code: QT

-

Posting Date: 2024-04-01

-

Reason Code: MAINTENANCE

-

External Document No.: MAINT-ANNUAL-001

Post: Complete annual maintenance documented

Posting the Component Journal

Before Posting

Verify:

-

All required fields filled (Asset No., Item No., Entry Type, Quantity, Posting Date)

-

Quantities correct (positive/negative as appropriate)

-

Reason codes entered (recommended)

-

External references documented

-

Batch contains correct lines

Review Lines: Scroll through all lines in batch

How to Post

Method 1: Post Button

Step 1: Click Post

-

Open Component Journal

-

Verify lines

-

Click Post button (ribbon)

-

Posting starts

Step 2: Automatic Processing

-

Each journal line creates one Component Entry

-

Entry No. assigned automatically

-

Transaction No. assigned (groups related entries)

-

User ID stamped

-

Lines deleted from journal after successful posting

Step 3: Confirmation

-

"Journal lines posted successfully" message

-

Lines removed from journal

-

Component Entries created

Method 2: Post and Print

Purpose: Post journal and view newly created entries

Steps:

-

Click Post and Print

-

Journal posts

-

Component Entries page opens

-

Filtered to today's entries

-

View/print entries

Benefit: Immediate verification of posted entries

What Happens on Posting

For Each Journal Line:

-

Validation:

-

All required fields present

-

Asset exists and not blocked

-

Item exists

-

Quantity not zero

-

-

Component Entry Created:

-

Entry No. assigned (auto-increment)

-

All fields copied from journal line

-

Transaction No. assigned

-

User ID stamped

-

Posted to Component Entry table

-

-

Journal Line Deleted:

-

Line removed from journal (successful posting)

-

Batch ready for new lines

-

Result: Permanent component ledger updated

Posting Errors

Error: "Asset No. must have a value"

Cause: Missing required field

Solution: Fill Asset No.

Error: "Item FILTER-OIL does not exist"

Cause: Item not in BC Item table

Solution: Create item first, then journal

Error: "Asset VEH-001 is blocked"

Cause: Asset blocked

Solution: Unblock asset or use different asset

Best Practices

Group Related Operations

Use Document No:

-

Same Document No. for related operations

-

Example: WO-2024-045 for all lines in one work order

Benefit: Link related component changes

Always Use Position

Why: Precise tracking

Example: Server with 8 disk bays

-

Position: "Bay 1" through "Bay 8"

-

Know exactly which bay has which drive

-

Faster troubleshooting

Consistency: Use standard naming (Bay 1, not BAY-1 or DISK1)

Track Serial Numbers

Always Enter For:

-

Hard drives

-

Memory modules

-

Expensive parts (>$500)

-

Warranty-tracked items

-

Safety-critical components

Benefit: Warranty claims, RMA tracking, failure analysis

Use Reason Codes Consistently

Standard Set:

-

MAINTENANCE - Scheduled maintenance

-

REPAIR - Repair operations

-

FAILURE - Component failure

-

UPGRADE - Component upgrade

-

RECALL - Manufacturer recall

-

AUDIT - Inventory audit

Train Team: Everyone uses same codes

Benefit: Meaningful reports, trend analysis

Document External References

External Document No:

-

Work order numbers

-

Service ticket IDs

-

RMA numbers

-

Purchase order references

Complete Traceability: Link to external systems

Post Regularly

Don't Wait: Post after each maintenance session

Why:

-

Immediate documentation

-

Fresh in memory

-

Catch errors early

-

Complete audit trail

Not: Batch up weeks of operations

Review Before Posting

Check:

-

All lines correct

-

No duplicate lines

-

Quantities make sense

-

Positions filled

-

External references documented

One-Time Review: Easier than fixing Component Entries later

Batch Management Best Practices

Separate Batches by Purpose

Standard Batches:

-

MAINTENANCE - Scheduled maintenance

-

REPAIR - Ad-hoc repairs

-

INSTALLATION - New component installs

-

AUDIT - Audit adjustments

Benefit: Organized workflow, clear separation

One Batch Per User (Optional)

Multi-User Environment:

-

USER1 batch

-

USER2 batch

-

Each user works in own batch

Benefit: No conflicts, clear ownership

Clear Batch After Posting

Result: Empty batch ready for next work

If Lines Remain: Review why (errors?)

Validation Rules

Asset Must Exist: Asset No. must be valid

Item Must Exist: Item No. must be in BC Item table

Quantity Required: Must specify quantity

Quantity Not Zero: Cannot post zero quantity

Posting Date Required: Must have valid date

Entry Type Required: Must select type

Troubleshooting

Problem: Cannot Find Component Journal

Solution:

-

Search "Component Journal" or "Asset Component Journal"

-

Check permissions (may need Component Management permission)

Problem: Batch Name Field Not Visible

Cause: May be looking at wrong page

Solution: Ensure "Asset Component Journal" page, Batch Name at top

Problem: Lines Disappear After Entering

Cause: Not saving properly or batch changed

Solution:

-

Verify batch selection

-

Don't change batch with unsaved lines

-

Press Esc to cancel if needed

Problem: Cannot Post - Validation Error

Common Errors:

-

Missing required fields (Asset No., Item No., Entry Type, Quantity, Posting Date)

-

Item doesn't exist in BC

-

Asset blocked or doesn't exist

-

Quantity = 0

Solution: Review error message, fix field, retry

Problem: Posted Lines Not Creating Entries

Cause 1: Posting failed with error (lines still in journal)

Solution: Read error message, fix issue

Cause 2: Permissions issue

Solution: Check Component Entry posting permissions

Problem: Need to Correct Posted Entry

Cannot Edit: Component Entries are permanent

Solution: Create Adjustment entry to correct

Example: Recorded wrong position

-

Create Adjustment entry with correct position

-

Document in description: "Correcting position from Bay 1 to Bay 2"

The Component Journal is your daily tool for maintenance documentation. Make it a habit: every component installed, removed, or replaced = one journal line. Post daily for complete, accurate component history. Use Position and Serial No. fields religiously - your future self will thank you when troubleshooting!