Component Ledger

The Component Ledger provides a complete, permanent audit trail of all parts installed in, removed from, or used with assets through Component Entries.

Understanding Component Entries

What is a Component Entry?

Component Entry = Permanent ledger record of a component operation

Created When:

-

Component Journal posted

-

Each journal line creates one Component Entry

-

Permanent, cannot be deleted

Purpose:

-

Complete installation/removal history

-

Maintenance audit trail

-

Compliance documentation

-

Service history

-

Failure analysis

Similar To:

-

Item Ledger Entries (for inventory)

-

Holder Entries (for asset custody)

-

G/L Entries (for accounting)

Entry Types

Install

Purpose: Component added to asset

Quantity: Positive

Examples:

-

Install new hard drive in server

-

Install 4 new tires on vehicle

-

Install air filter in HVAC

Interpretation: Component now in/on asset

Remove

Purpose: Component taken out of asset

Quantity: Negative (typically)

Examples:

-

Remove defective memory module

-

Remove worn brake pads

-

Remove old toner cartridge

Interpretation: Component no longer in asset

Replace

Purpose: Component replaced (combines remove + install)

Quantity: Positive (new component qty)

Examples:

-

Replace oil filter during service

-

Replace defective power supply

-

Replace worn belt

Interpretation: Old component out, new component in

Note: Single entry type for convenience, represents replacement operation

Adjustment

Purpose: Correct component records

Quantity: Can be positive or negative

Examples:

-

Correct quantity after physical audit

-

Fix data entry error

-

Adjust position information

Interpretation: Record correction

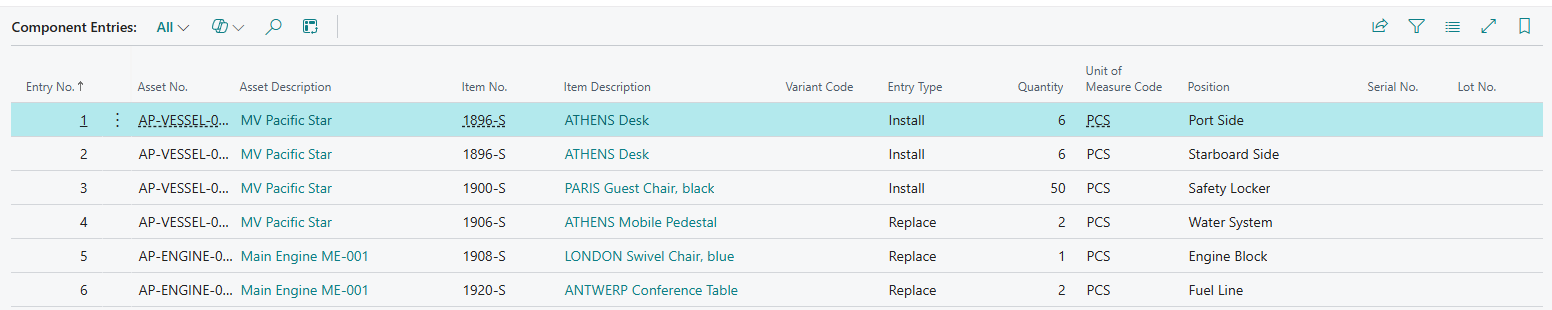

Component Entry Fields

Entry No.

Type: Integer

Auto-Assigned: Yes

Unique: Yes

Purpose: Unique identifier for this entry

Usage: Reference in investigations, reports

Asset No.

Type: Code[20]

Required: Yes

Links To: Asset Pro Asset table

Purpose: Which asset this component operation is for

Example: VEH-001, SRV-WEB-01, PRINTER-LAB

Lookup: Opens Asset List

Asset Description (FlowField)

Type: Text[100]

Calculated: Yes

Editable: No

Purpose: Asset name for readability

Auto-Populated: From Asset record

Item No.

Type: Code[20]

Required: Yes

Links To: Business Central Item table

Purpose: Which component (part/item)

Example: FILTER-OIL, HDD-2TB, TONER-BLK

Lookup: Opens Item List

Requirement: Item must exist in BC Item table

Item Description (FlowField)

Type: Text[100]

Calculated: Yes

Editable: No

Purpose: Item name for readability

Auto-Populated: From Item record

Variant Code

Type: Code[10]

Optional: Yes

Links To: Item Variant

Purpose: Specific item variant if applicable

Example: Item "TIRE", Variant "17-INCH"

Entry Type

Type: Enum

Required: Yes

Options: Install, Remove, Replace, Adjustment

Purpose: What operation was performed

Critical: Determines interpretation of quantity and operation

Quantity

Type: Decimal

Required: Yes

Precision: 0-5 decimals

Purpose: How many components

Sign Interpretation:

-

Install: Positive (adding components)

-

Remove: Negative (taking out components)

-

Replace: Positive (new components)

-

Adjustment: Positive or negative (correction)

Example: 4 (four tires installed)

Unit of Measure Code

Type: Code[10]

Links To: Item Unit of Measure

Optional: Yes

Purpose: Unit for quantity

Examples: PCS (pieces), QT (quarts), GAL (gallons)

Default: Item's Base Unit of Measure

Position

Type: Text[50]

Optional: Yes (but recommended)

Purpose: Physical location within asset

Examples:

-

"Front Left Wheel"

-

"Disk Bay 3"

-

"Slot A1"

-

"Engine Compartment"

-

"Cartridge Tray 1"

Benefit: Precise tracking, faster maintenance

Serial No.

Type: Code[50]

Optional: Yes

Purpose: Serial number for serialized components

Examples:

-

Hard drive: HDD-SN-8472947

-

Memory: MEM-12345678

-

Battery: BAT-SN-2024-001

When to Use:

-

Serialized parts

-

Warranty tracking

-

Expensive components

-

RMA requirements

Lot No.

Type: Code[50]

Optional: Yes

Purpose: Lot/batch number

Examples:

-

Filter lot: LOT-2024-Q1-001

-

Oil batch: BATCH-5W30-2024

When to Use:

-

Lot-tracked items

-

Quality control

-

Recall management

Posting Date

Type: Date

Required: Yes

Purpose: When component operation occurred

Usage: Historical tracking, maintenance schedules

Example: 2024-03-15

Reason Code

Type: Code[10]

Optional: Yes (recommended)

Links To: BC Reason Code

Purpose: Why component operation happened

Common Codes:

-

MAINTENANCE - Scheduled maintenance

-

REPAIR - Repair/replacement

-

FAILURE - Component failure

-

UPGRADE - Component upgrade

-

RECALL - Manufacturer recall

-

AUDIT - Inventory audit adjustment

Document Type

Type: Enum

Optional: Yes

Purpose: Source document type

Options: Component Journal, Item Journal (future), etc.

Document No.

Type: Code[20]

Optional: Yes

Purpose: Source document number

Example: COMP-JNL-2024-001, WO-12345 (work order)

Usage: Link to source, group related operations

External Document No.

Type: Code[35]

Optional: Yes

Purpose: External reference

Examples:

-

Work Order: WO-2024-12345

-

Service Ticket: TICKET-8472

-

Purchase Order: PO-VEN-001

-

RMA: RMA-VENDOR-789

Benefit: Complete traceability to external systems

Transaction No.

Type: Integer

Auto-Assigned: Yes

Purpose: Group related entries

Usage: Future - link related operations (e.g., remove + install in replace)

User ID

Type: Code[50]

Auto-Assigned: Yes

Editable: No

Purpose: Who created this entry

Usage: Audit trail, accountability

Example: MAINTENANCE-USER-1

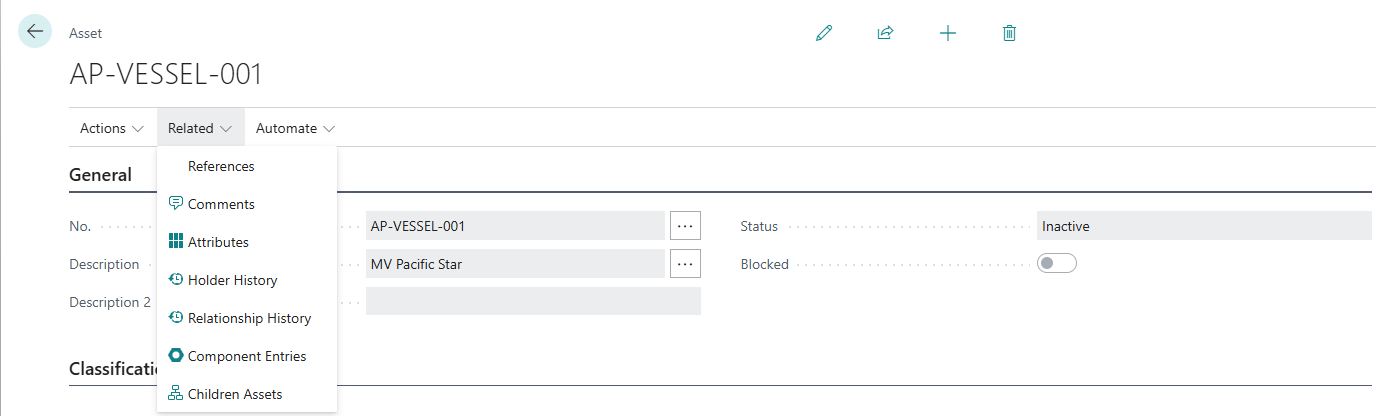

Viewing Component Entries

From Asset Card

Step 1: Open Asset Card

Step 2: Click Actions → Component Entries

Step 3: Component Entries page opens, filtered to this asset

Result: All components for this asset

From Component Entries Page

Method 1: Direct Search

-

Press Alt+Q

-

Enter "Component Entries"

-

Choose related link

-

Page opens (all entries)

Method 2: From Role Center

-

Navigate: Maintenance → Component Entries

-

Page opens

Filtering Component Entries

By Asset:

-

Filter: Asset No. = VEH-001

-

Shows: All components for vehicle VEH-001

By Item:

-

Filter: Item No. = FILTER-OIL

-

Shows: All uses of oil filters

By Date Range:

-

Filter: Posting Date = 01/01/2024..03/31/2024

-

Shows: Q1 component operations

By Entry Type:

-

Filter: Entry Type = Install

-

Shows: All installations

By Reason:

-

Filter: Reason Code = MAINTENANCE

-

Shows: Scheduled maintenance operations

Combined Filters:

-

Asset = VEH-001 AND Posting Date = Last 30 Days

-

Shows: Recent operations on vehicle

Component History Analysis

Current Component Configuration

Question: "What components are currently installed in Server SRV-001?"

Method:

-

Filter: Asset No. = SRV-001

-

Group by Item No.

-

Sum: Install/Replace entries (positive)

-

Subtract: Remove entries (negative)

-

Result = Current installed quantity

Example:

-

Hard Drive HDD-2TB: 4 Install entries - 1 Remove entry = 3 currently installed

-

Memory MEM-8GB: 8 Install entries = 8 currently installed

Future Enhancement: Calculated field for "Current Qty"

Maintenance Timeline

Question: "What's the maintenance history for Vehicle VEH-001?"

Method:

-

Filter: Asset No. = VEH-001

-

Sort by: Posting Date (ascending)

-

View chronologically

Result: Timeline view

Example:

2024-01-15: Oil Filter (Replace) - Reason: MAINTENANCE 2024-01-15: Engine Oil (Install, 5 QT) - Reason: MAINTENANCE 2024-02-20: Brake Pads (Replace, 4 PCS) - Reason: REPAIR 2024-03-15: Air Filter (Replace) - Reason: MAINTENANCE

Component Failure Analysis

Question: "How often do Hard Drives fail?"

Method:

-

Filter: Item No. = HDD-2TB

-

Filter: Reason Code = FAILURE

-

Count entries

-

Date range: Last 12 months

-

Calculate: Failures per month

Result: Failure rate data

Use: Vendor evaluation, preventive replacement scheduling

Consumable Usage

Question: "How many oil filters used this quarter?"

Method:

-

Filter: Item No. = FILTER-OIL

-

Filter: Entry Type = Install OR Replace

-

Date range: Q1 2024

-

Sum Quantity

Result: 45 filters (example)

Use: Purchase planning, budget analysis

Serial Number Tracking

Question: "Where is Hard Drive with Serial HDD-12345?"

Method:

-

Filter: Serial No. = HDD-12345

-

Find latest Install or Replace entry

-

Asset No. shows current location

Result: Asset SRV-WEB-01

Use: Warranty claims, RMA tracking, asset location

Component Entries vs. Item Ledger Entries

Component Entries: Track components IN RELATION TO ASSETS

Item Ledger Entries: Track inventory movements

| Aspect

|

Component Entries

|

Item Ledger Entries

| | --- | --- | --- | |

Focus

|

Asset-component relationship

|

Inventory transactions

| |

Tracks

|

Installed where, when

|

Qty on hand, cost

| |

Key Field

|

Asset No.

|

Location, Bins

| |

Purpose

|

Maintenance history

|

Inventory control

| |

Example

|

"Filter installed in Vehicle VEH-001"

|

"50 filters in warehouse"

|

Both Can Exist: Installing component CAN create both (if integrated)

Currently: Component Entries separate (inventory integration future)

Reporting Use Cases

Maintenance Schedule Compliance

Report: Scheduled maintenance completion

Method:

-

Filter: Reason Code = MAINTENANCE

-

Group by: Asset No., Month

-

Verify: All assets serviced per schedule

Output: Compliance report

Component Lifecycle

Report: Component lifespan from install to remove

Method:

-

Filter: Item No. = specific component

-

Match: Install entry (date1) with Remove entry (date2) for same Asset + Position

-

Calculate: date2 - date1 = Lifespan

Output: Average component lifespan

Use: Replacement scheduling, vendor evaluation

Warranty Tracking

Report: Components under warranty

Method:

-

Filter: Item No. = warranty-tracked item

-

Filter: Entry Type = Install

-

Calculate: Posting Date + Warranty Period = Warranty Expiry

-

Filter: Warranty Expiry > Today

Output: Components still under warranty

Cost Analysis

Report: Component costs per asset

Method:

-

Filter: Asset No. = specific asset

-

Join: Component Entry → Item → Unit Cost

-

Sum: Quantity × Unit Cost

Output: Total component cost for asset

The Component Ledger is your complete maintenance history. Use it to analyze failure patterns, schedule preventive maintenance, track warranty coverage, and ensure compliance. Export to Excel for advanced analysis and trending!