Asset Pro Basics

Before diving into daily operations, understand these core concepts and terminology. This foundation will help you work effectively with Asset Pro.

Core Concepts

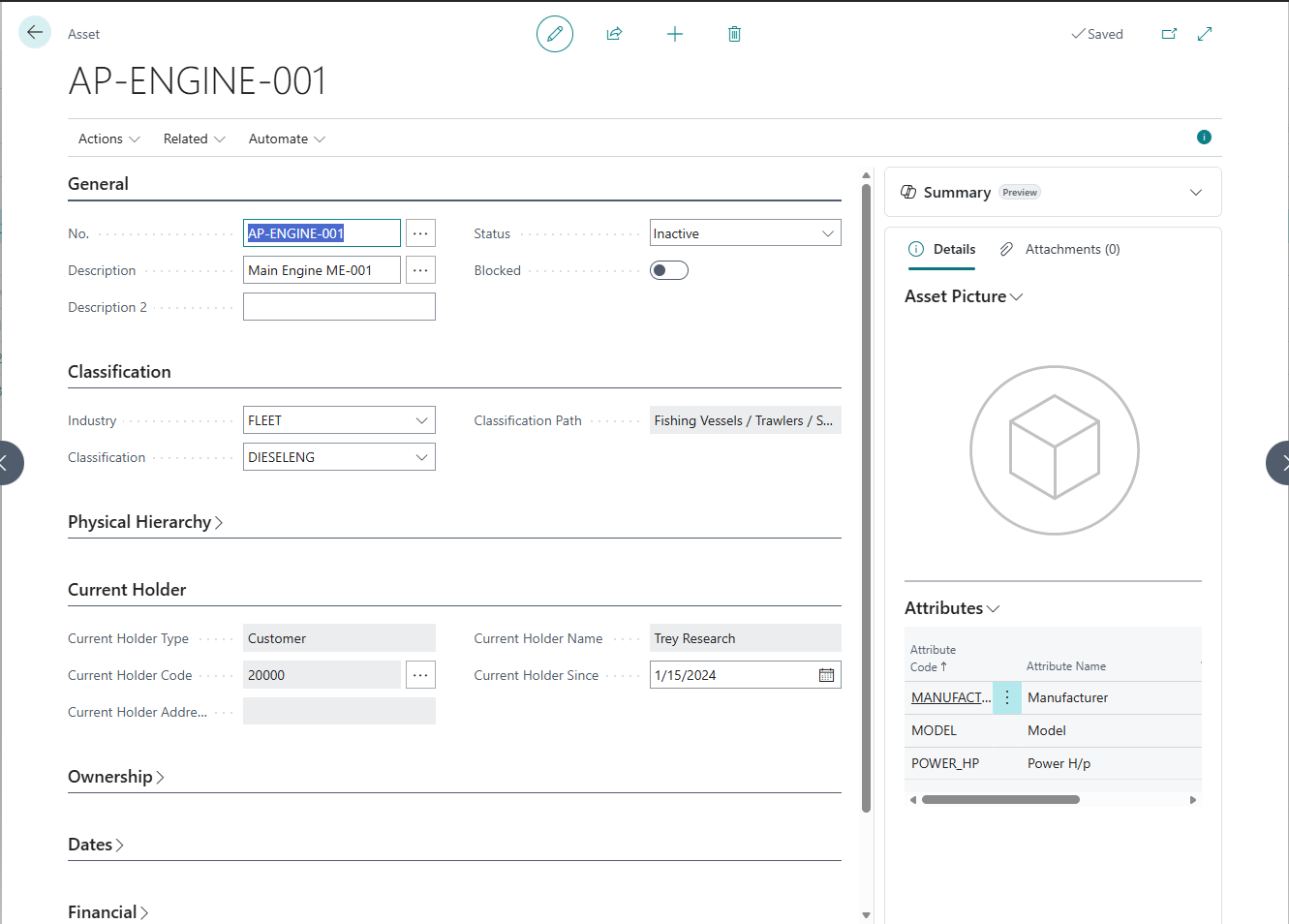

What is an Asset?

Asset = A physical item you want to track

An asset in Asset Pro represents any physical object your organization needs to monitor:

-

Equipment: Computers, machinery, vehicles

-

Devices: Medical equipment, IT hardware, tools

-

Vehicles: Ships, trucks, cars, aircraft

-

Machinery: Production equipment, construction equipment

Key Point: Assets are physical items, not financial assets. Asset Pro tracks custody, location, and movement - not financial depreciation.

Each asset has:

-

Unique number (auto-generated)

-

Description and specifications

-

Current holder (who has it now)

-

Industry and classification

-

Complete custody history

-

Optional parent-child relationships

-

Optional custom attributes

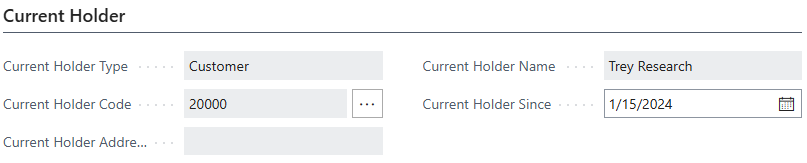

What is a Holder?

Holder = Who currently has custody of the asset

The "holder" is whoever or wherever currently possesses the asset. Asset Pro supports 4 holder types:

1. Location (Most common)

-

Physical locations within your organization

-

Examples: MAIN, WAREHOUSE, BRANCH-EAST, PORT-MIAMI

-

Standard BC Location table

-

Use for: Assets at company facilities

2. Customer

-

Assets at customer locations

-

Examples: Rented equipment, assets under service, sold assets

-

Standard BC Customer table

-

Use for: Customer-facing assets, rentals, service assets

3. Vendor

-

Assets with vendors

-

Examples: Equipment at repair shop, assets in maintenance

-

Standard BC Vendor table

-

Use for: Repair, maintenance, consignment

4. Employee (Coming in future versions)

-

Assets assigned to employees

-

Examples: Laptops, company vehicles, tools

-

Standard BC Employee table

-

Use for: User-assigned equipment

Current Holder Fields:

-

Current Holder Type: Location, Customer, or Vendor

-

Current Holder Code: Specific location/customer/vendor

-

Both fields together = complete holder information

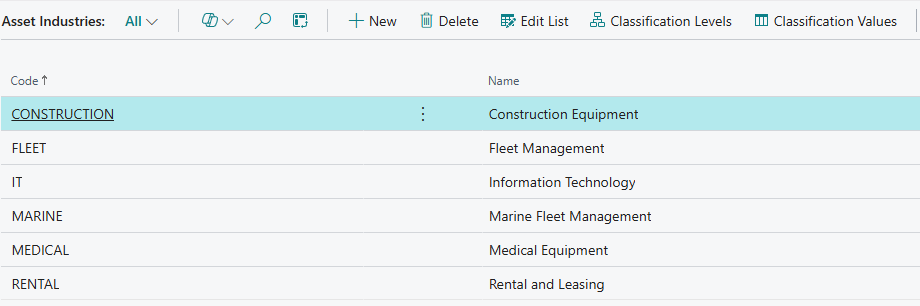

What is an Industry?

Industry = Top-level organizational container

Industries provide the highest level of organization in Asset Pro. Each industry represents a distinct business area with its own:

-

Classification structure (Type → Category → Model)

-

Custom terminology (Vessels, Devices, Equipment)

-

Custom attributes (Cargo Capacity, RAM, Field Strength)

Examples:

-

FLEET (Fleet Management)

-

MEDICAL (Medical Equipment)

-

IT (IT Assets)

-

MANUF (Manufacturing Equipment)

-

CONST (Construction Equipment)

Why Industries?:

-

Separate classification hierarchies for different business areas

-

Industry-specific terminology

-

Industry-specific custom fields

-

Support multiple business units in one system

One Asset → One Industry (assets cannot span industries)

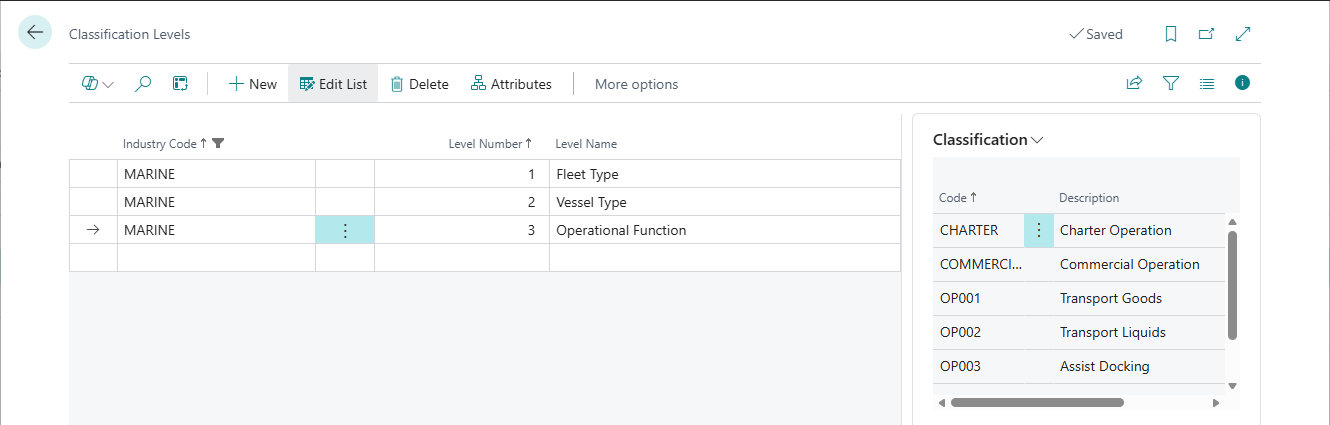

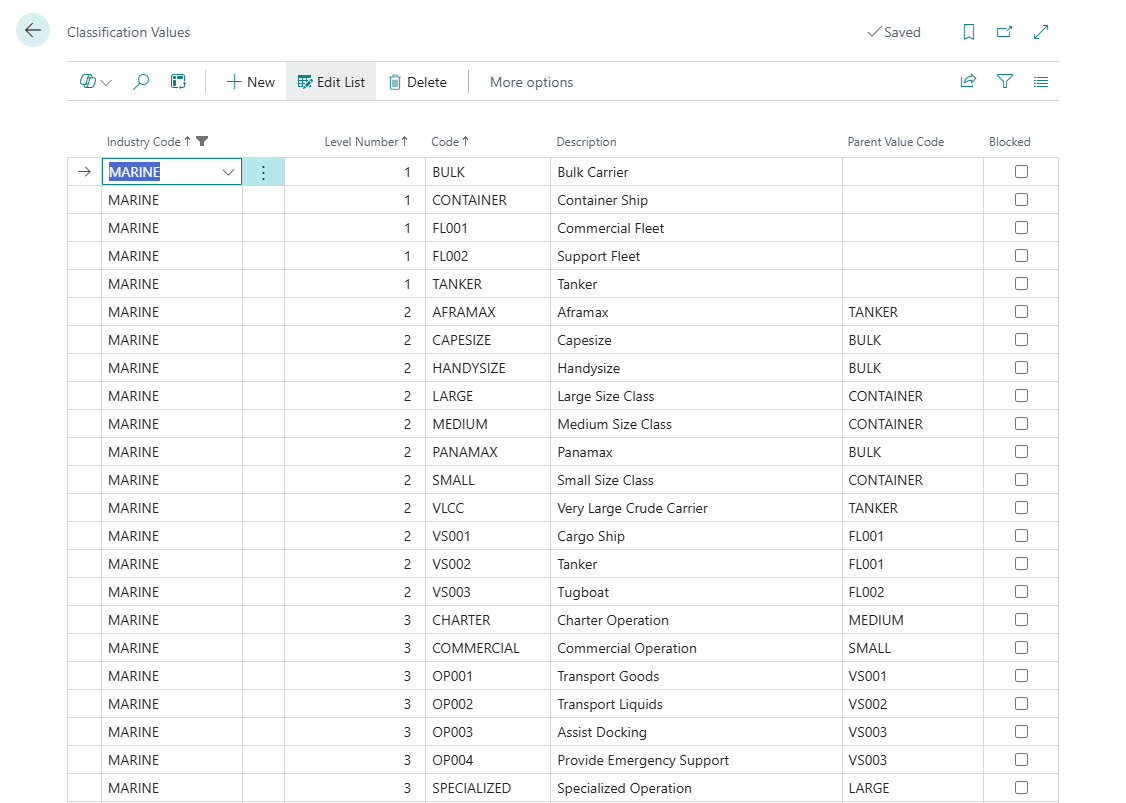

What is Classification?

Classification = Hierarchical categorization (What IS the asset?)

Classification provides structured categorization using hierarchical levels:

Classification Structure:

Industry: FLEET ├─ Level 1: Fleet Type │ ├─ COMMERCIAL (Commercial Vessels) │ ├─ FISHING (Fishing Vessels) │ └─ PASSENGER (Passenger Vessels) ├─ Level 2: Vessel Category │ ├─ CARGO (Cargo Ships) → parent: COMMERCIAL │ ├─ TANKER (Tankers) → parent: COMMERCIAL │ └─ FERRY (Ferries) → parent: PASSENGER └─ Level 3: Vessel Model ├─ PANAMAX (Panamax Bulk Carrier) → parent: CARGO └─ VLCC (Very Large Crude Carrier) → parent: TANKER

Key Features:

-

Hierarchical: Parent-child relationships between levels

-

Flexible: 2-50 levels per industry

-

Custom terminology: Name levels to match your business

-

Filterable: Filter assets by any level

Classification vs. Parent-Child:

-

Classification = What IS it (organizational category)

-

Parent-Child = What's INSIDE it (physical composition)

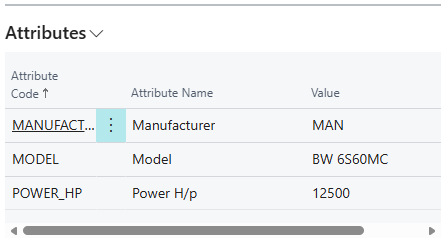

What are Attributes?

Attributes = Custom fields specific to industry or classification

Attributes provide industry-specific data fields without code modifications:

Example - Fleet Industry Attributes:

-

Cargo Capacity (Decimal): 50000.00 TEU

-

IMO Number (Text): IMO 1234567

-

Flag Country (Text): Panama

-

Vessel Condition (Option): Excellent, Good, Fair, Poor

-

Last Survey Date (Date): 2024-01-15

-

Crew Size (Integer): 25

Supported Data Types:

-

Text (codes, names, descriptions)

-

Integer (counts, years, whole numbers)

-

Decimal (measurements, capacities)

-

Date (dates, expirations)

-

Boolean (yes/no, enabled/disabled)

-

Option (predefined choices: Excellent, Good, Fair, Poor)

Attribute Levels:

-

Level 0 (Industry): Applies to ALL assets in industry

-

Level 1-N (Classification): Applies only to assets at specific classification level

Enable/Disable: Controlled by "Enable Attributes" toggle in Asset Setup

Key Workflows

Creating an Asset

Basic Workflow:

-

Navigate to Asset List

-

Click New

-

Fill in required fields:

-

Description: Human-readable name

-

Industry Code: Select industry (FLEET, IT, etc.)

-

Classification values: Select Type, Category, Model

-

Current Holder: Select Location/Customer/Vendor

-

-

Fill optional fields:

-

Manufacturer, Model, Serial No.

-

Custom attributes (if enabled)

-

Notes, dimensions, specifications

-

-

Click OK to save

Result: Asset created with auto-generated number (e.g., ASSET-0001)

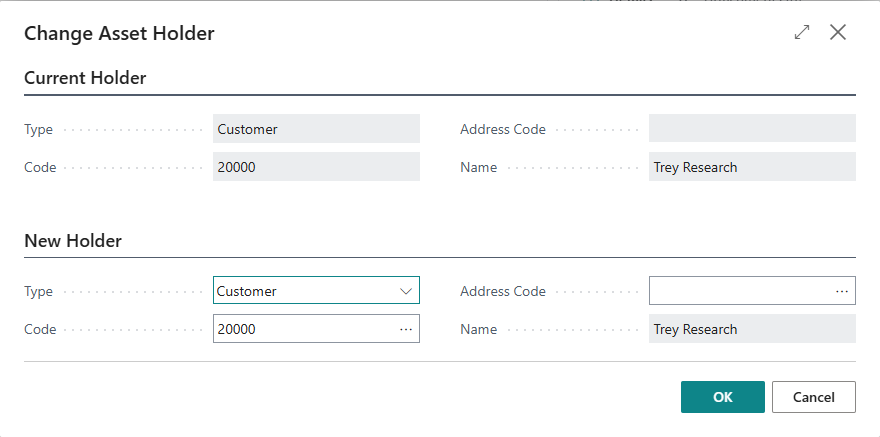

Changing Asset Holder

4 Methods Available:

1. Asset Journal (Batch processing)

-

Move multiple assets at once

-

Quick corrections

-

Posting date validation

-

See: Asset Journal

2. Asset Transfer Orders (Formal workflow)

-

Open → Released → Posted workflow

-

Shipment and receipt steps

-

Permanent archive

-

See: Asset Transfer Orders

3. Document Integration (Automatic)

-

Purchase documents: Vendor → Location

-

Sales documents: Location → Customer

-

Transfer documents: Location → Location

-

See: Document Integration

4. Manual Holder Change (Optional - if not blocked)

-

Direct edit on Asset Card

-

Auto-registered with "MAN-" prefix

-

Requires "Block Manual Holder Change" = unchecked in Setup

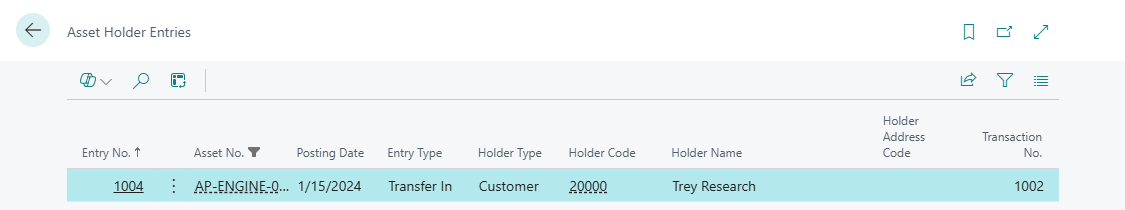

Viewing Holder History

Every holder change creates Holder Entries:

To View:

-

Open Asset Card

-

Navigate → Holder Entries

-

See complete custody history

Holder Entry Types:

-

Transfer Out: Asset left holder

-

Transfer In: Asset arrived at holder

Always in pairs: Every transfer creates both OUT (from old holder) and IN (to new holder)

Entry Fields:

-

Entry No. (unique identifier)

-

Asset No.

-

Entry Type (Transfer Out / Transfer In)

-

Holder Type & Code

-

Posting Date

-

Document No. (reference to journal/transfer/document)

-

Transaction No. (groups related transfers)

Point-in-Time Queries: "Who had Asset-0001 on 2024-01-15?" → Query holder entries

Three-Layer Architecture

Asset Pro uses three distinct structural layers:

Layer 1: Classification Hierarchy (What IS it?)

Purpose: Organizational categorization

Structure: Industry → Level 1 → Level 2 → Level 3

Example:

Fleet Management → Commercial Vessels → Cargo Ship → Panamax Bulk Carrier

Use: Filter, group, and organize assets by business taxonomy

Layer 2: Physical Hierarchy (What's INSIDE it?)

Purpose: Physical composition and assembly

Structure: Parent → Child → Grandchild

Example:

Vessel "ATLANTIC STAR" ├─ Main Engine "ENG-001" │ └─ Turbocharger "TURBO-001" └─ Auxiliary Engine "ENG-002"

Features:

-

Attach/detach events tracked

-

Relationship Entries (audit trail)

-

Automatic transfer propagation (children follow parent)

-

Cannot directly transfer child (must transfer parent)

Use: Track what components are installed in what assets

Layer 3: Components (What PARTS does it use?)

Purpose: Link assets to standard BC Items

Structure: Asset → Item (standard BC Item table)

Example:

Vessel "ATLANTIC STAR" ├─ Installed: Oil Filter (ITEM: FILTER-001) on 2024-01-10 ├─ Installed: Fuel Injector (ITEM: INJECT-200) on 2024-01-12 └─ Removed: Old Filter (ITEM: FILTER-001) on 2024-03-10

Features:

-

Component Ledger (installation/removal history)

-

Item Journal integration (automatic component entries)

-

Links to inventory management

Use: Track parts consumed/installed in assets

See: Component Management

Data Integrity Features

Posting Date Validation

Rule: Cannot backdate transfers before asset's last holder entry

Why: Ensures chronological integrity of custody audit trail

Example:

-

Last holder entry: 2024-03-15

-

Try to transfer with posting date: 2024-03-10

-

Result: Error - "Cannot backdate before last entry"

Applies To:

-

Asset Journal

-

Asset Transfer Orders

-

Manual holder changes

-

Document integration

Hierarchy Integrity

Circular Reference Prevention:

-

Cannot create: Asset A → parent: Asset B → parent: Asset A

-

System detects and blocks circular relationships

Maximum Depth:

-

100 levels maximum

-

Prevents infinite recursion

Subasset Protection:

-

Cannot transfer child directly

-

Must transfer parent (children follow automatically)

-

Maintains family integrity

Holder Validation

Before Transfer:

-

Asset must be at expected "from" holder

-

Purchase receipts: Asset must be held by vendor

-

Sales shipments: Asset must be at location

-

Prevents transferring asset you don't have

Key Terminology Quick Reference

| Term

|

Definition

| | --- | --- | |

Asset

|

Physical item being tracked

| |

Holder

|

Current custodian (Location, Customer, Vendor)

| |

Industry

|

Top-level organizational container

| |

Classification

|

Hierarchical categorization (Type → Category → Model)

| |

Attribute

|

Custom field specific to industry/classification

| |

Parent-Child

|

Physical relationship (Engine inside Ship)

| |

Component

|

Standard BC Item installed in asset

| |

Holder Entry

|

Audit record of custody change

| |

Transfer Order

|

Formal document for asset movement

| |

Asset Journal

|

Batch tool for manual holder changes

| |

Classification Level

|

One level in hierarchy (e.g., "Fleet Type")

| |

Classification Value

|

Specific option (e.g., "Commercial Vessels")

| |

Posting Date

|

Effective date of holder change

| |

Transaction No.

|

Groups related transfers together

|

Common Patterns

Pattern 1: New Asset Received from Vendor

Scenario: Purchased new equipment, receiving from vendor

Steps:

-

Asset already exists in system (created beforehand)

-

Asset holder = Vendor

-

Create purchase receipt with asset line

-

Post receipt

-

Result: Asset holder automatically changes: Vendor → Location

See: Purchase Document Integration

Pattern 2: Asset Sold/Rented to Customer

Scenario: Selling/renting equipment to customer

Steps:

-

Asset at Location

-

Create sales order with asset line

-

Post shipment

-

Result: Asset holder automatically changes: Location → Customer

See: Sales Document Integration

Pattern 3: Internal Move Between Locations

Scenario: Moving asset from MAIN to WAREHOUSE

Method A - Asset Journal (Quick):

-

Open Asset Journal

-

Add line: Asset-0001, From: MAIN, To: WAREHOUSE

-

Post journal

-

Result: Holder changed with MAN- document

Method B - Transfer Order (Formal):

-

Create transfer order: MAIN → WAREHOUSE

-

Add asset line

-

Release transfer order

-

Post shipment (asset leaves MAIN)

-

Post receipt (asset arrives WAREHOUSE)

-

Result: Formal archived transfer document

See: Asset Journal | Transfer Orders

Pattern 4: Asset to Vendor for Repair

Scenario: Sending equipment to repair vendor

Steps:

-

Asset at Location

-

Create purchase return order with asset line

-

Post return shipment

-

Result: Asset holder: Location → Vendor (at repair shop)

When Repaired:

-

Create purchase order (or receipt) for same asset

-

Post receipt

-

Result: Asset holder: Vendor → Location (returned from repair)

See: Purchase Document Integration

Best Practices

Asset Numbering

-

Use AI Name Suggester for professional, consistent names

-

Include key identifiers (model, serial, year) in description

-

Leverage auto-numbering for unique IDs

Holder Management

-

Always know where assets are (Current Holder must be accurate)

-

Use appropriate transfer method for situation

-

Review Holder Entries regularly for audit purposes

Classification

-

Design classification hierarchy before creating many assets

-

Use AI Setup Wizard for automatic structure generation

-

Keep classification levels consistent within industry

Attributes

-

Only enable attributes if you'll use them

-

Define attributes at correct level (industry vs. classification)

-

Use Option type for predefined choices (better than Text)

Documentation

-

Use Document No. in holder entries for traceability

-

Link asset references to purchase/sales documents

-

Maintain notes on Asset Card for important information

Don't try to learn everything at once. Start with creating a few test assets, move them between locations using Asset Journal, and view the Holder Entries. Once comfortable with basic operations, explore advanced features like parent-child relationships and document integration.